|

Eco-friendly Flame Retardant |

|---|

|

|

||||||||||||||||||||||||

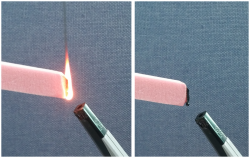

This is an eco-freindly flame retardant masterbatch for XPS, which is widely used for the insulation material of the outer walls. |

||||||||||||||||||||||||

1. Brief Introduction HBCD flame retardant has been widely being used for XPS up to now. But an Eco-friendly flame retardant is now gaining more interesting as an alternative of the existing HBCD because of overall restriction on the use of such hazardous material as HBCD, which is to be effected from 2017. Our eco-friendly flame retardant M/B has reduced the emission of the environmental pollution materials and improved the flame retardance.

2. Features & Advantages of our Eco-friendly flame retardant M/B - High Heat Resistance - Good restriction on the generation of smoke - Better flow property of resin - Improve the strength of the product

3. Major Uses - XPS Boards for heat insulation of outer walls

4. Specification

5. Cautions in Use 1) As the meltin point of the major flame retardant materila is relatively low, it is recommended to use twin screw extruder at lower temperature in the feeding pot of the raw materials if possible. 2) In order to prevent the occurrence of flow fluctuation phenomenon at production process, it is required to mix the flame retardant M/B with PS resin evenly and sufficiently prior to production.

6. Packing - 25kg kraft bag with plastic lining, 1ton/pallet

7. Storage and Transportation - keep at cool & dry place and avoid the direct sunlight. - transport same as other plastics.

|