1. Brief Introduction

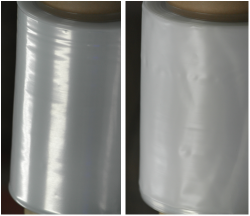

Generally blown films or low density resins have a gloss when extruded. This gloss can be eliminated by adding Matting Masterbatch. This masterbatch has been developed to make the plastic products like films show such friendly texture as natural substances by restricting the generation of gloss from the produced films as much as possible, and is widely being used by many film manufacturers under good reputation.

Matt products makes us feel very comfortable for the natural contact feeling and easy look.

The gloss level is variable subject to the kind of resin (LDPE or HDPE), the forming type (blown film or blow casting) and machine parameters (temperature, elongation), etc.

2. Features & Advantages of Matting Masterbatch

- Good printing property (but difficulty in case of bocaci printing)

- Improved opening property because of no blocking phenomenon

- No problem in sealing

3. Cautions in Use

? When storage Matting Masterbatch for a long period of time without using, it may absorbs the moisture in the air. As the high content moisture may cause some troubles in the production process, Matting Masterbatch should be sealed and then kept at the place in which both moisture content and temperature are low.

? If the humidity content is very high, it is recommended to use Matting Masterbatch after drying them or to add our Super Dehumidifying Masterbatch (Dosage 2%).

4. Information required to design the recipe of Matting Masterbatch

- The kind of the resin used by client (in case of mixed resins, the mixing ratio of each resin)

- The kind of machines (of blown film or of blow cast?)

- Single layer film or multi-layer film?

It is possible to work without changing any specific machine parameter and more detailed data are available if required.

5. Major Uses

In case of films => disposable vinyl gloves, rain coats, shopping bags, diaper, pad, food packagings, etc.

In case of sheets => disposable cups/trays, trays for food packaging, etc.

6. Grade per Use

|

Item |

GRADE |

Resin |

Dosage(%) |

Uses |

Remark |

|

MAT |

710 |

LD/LLDPE |

25~30 |

Blown Films |

|

|

MAT |

720 |

PP |

15~30 |

Sheets |

|

|

MAT |

730 |

PET |

20~30 |

Blow Molding |

|

|