1. What's a Foam Masterbatch?

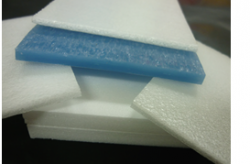

Foam Masterbatch as an additive used in extrusion or injection molding after mixed with resins is used to reduce the weight, increase the heat insulation property, prevent the compression due to heat deflection when chilled and transform the unique properties of plastics as a small elastomer by making small air holes (independent bubbles).

2. Kinds of Foam Agents

There are two groups in large scale depending on their uses; one is inorganic and the other is organic. Foaming activity of inorganic is higher than that of organic, whereas it is inconvenient to handle because the size of foamed cell is big and sensitive to humidity.

3. Cautions when choose Foam Agent

- Kind of the resin to foam

- Foam Ratio (Specific Gravity)

- Cell Size

- Purpose/Use of Foaming

- Product Color (Yellowish phenomenon may occur for organic)

4. Foaming Machine

Both blow type and cast type should be available. However, foamed cells may be different considerably depending on screw type and dies, etc. As the quality of Foam Agent is decided depending on the chilling after foaming, it is important to choose the right chilling system. It is most important to chill upon product discharged.

5. Recommended Grade per Use

|

Item |

Grade |

Applicable Resin |

Dosage (%) |

Uses |

Remark |

|

FOA |

916 |

LD. HDPE. PP |

3 |

for

Films, Sheets,

Injection Molding |

Fine Cell |

|

FOA |

947 |

LD. HDPE. PP |

3 |

for

Films, Sheets,

Injection Molding |

|

|

FOA |

915 |

LD. HDPE. PP |

3 |

for

Films |

Large volume of Gas |

|

FOA |

906 |

PS |

3 |

for Sheets, Injection

Molding |

|

|